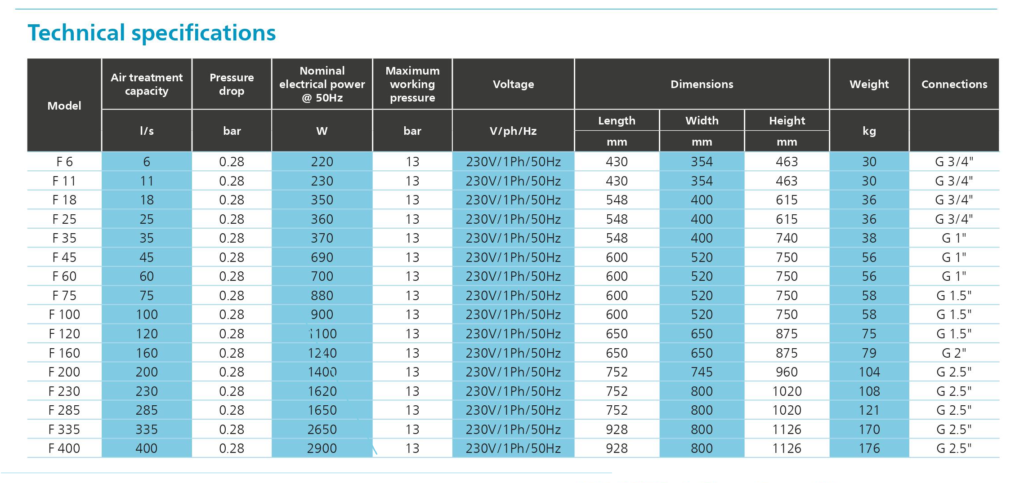

Compressed Air Dryers ~ F Series

Atlas Copco F-series refrigerant dryers keep your compressed air system in optimal shape, removing humidity efficiently and reliably. With a stable pressure dewpoint as low as 7°C, these compact, low-maintenance dryers are compatible with most compressor technologies and applications.

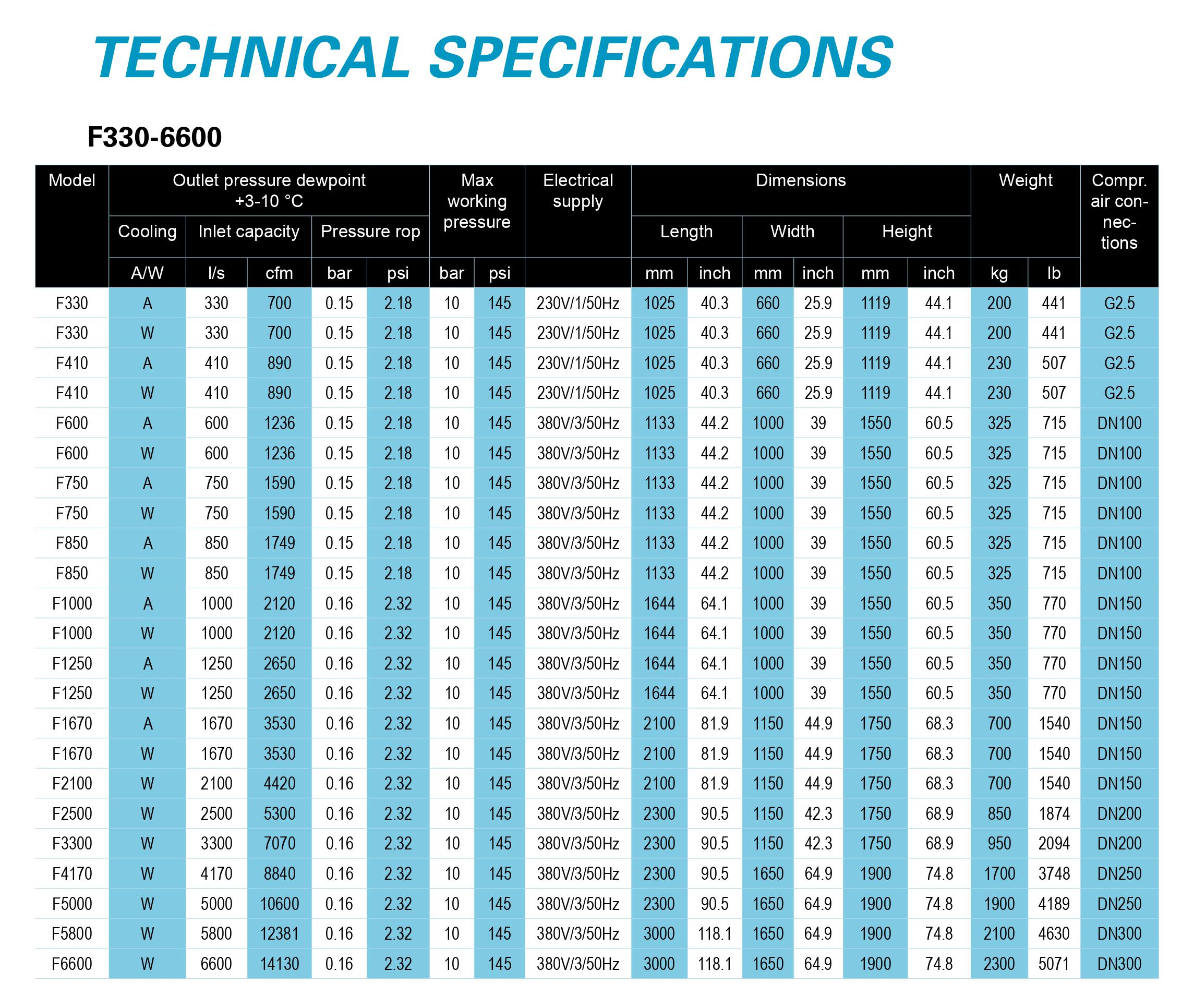

F series (330-6600 l/s, 700-14000 cfm)

REFRIGERANT AIR DRYERS F series (330-6600 l/s, 700-14000 cfm)

The refrigerant circuit compresses and expands the refrigerant medium in a circular system in order to efficiently transfer heat from the wet compressed air to the atmosphere. The F dryer’s refrigerant circuit is designed as a whole and only uses components of high and reliable quality, supplied by globally recognized manufacturers.

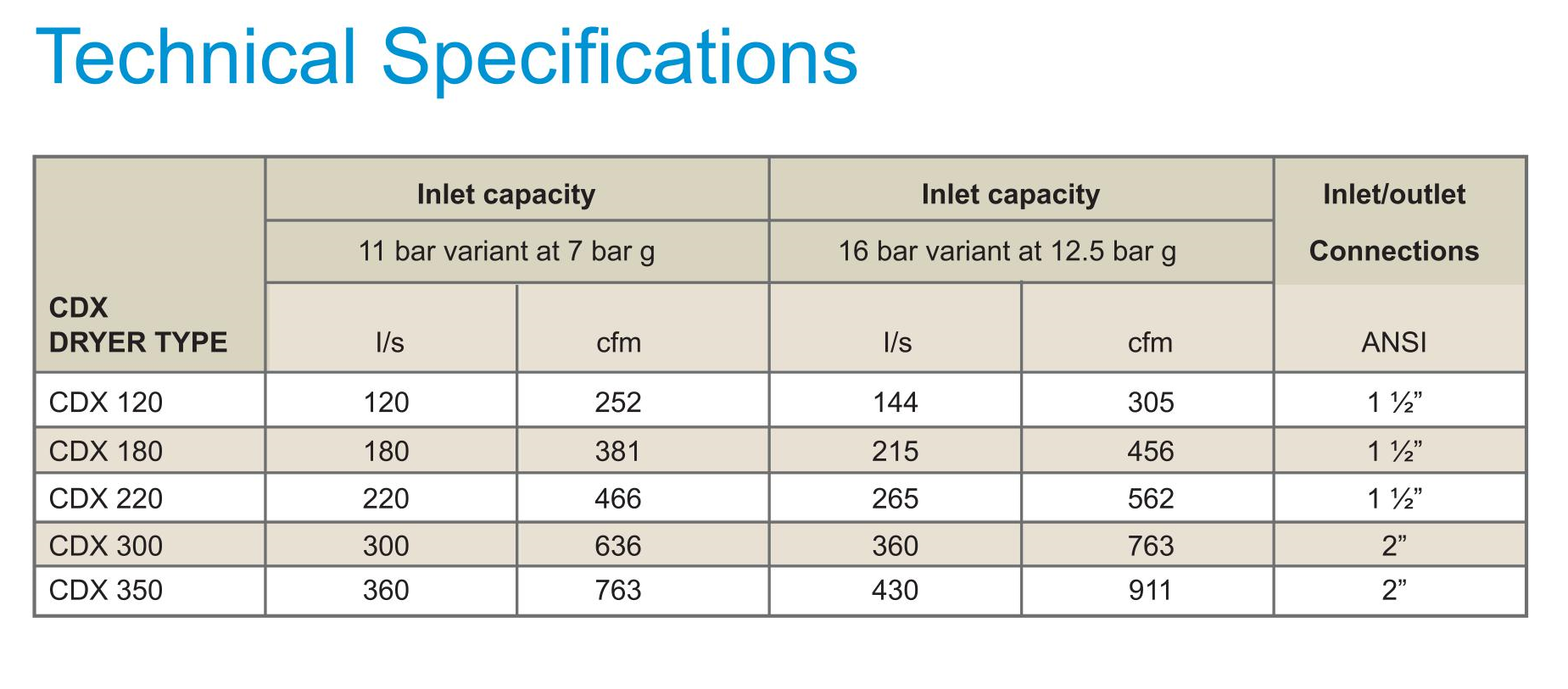

CDX SERIES

Atlas Copco Heatless adsorption compressed Air dyer

compressed air entering the air net is always 100% saturated with water vapour. when cooling down, this moisture will condense, causing damage to your air system and to your finished products. The amount of water is directly proportional to the flow and although an aftercooler will eliminate 2/3 of the moisture, the remaining third can still be very destructive in many application, such as instrument air, dry powder conveying or processes with rapid air expansion.